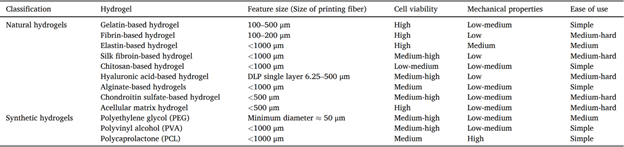

Hydrogels are a common material used in biomedical applications. They make excellent scaffolds due to their ability to closely mimic the extracellular matrix [1]. They can be made from a variety of natural or synthetic polymers. These polymers can be used as bioinks to print scaffolds for cells to grow around. A summary of natural and synthetic polymers used as bioinks is shown below.

It is hard for a single hydrogel to satisfy both cell viability and mechanical properties. This is especially true for cartilage which must have extremely robust mechanical properties since it is responsible for distributing the force across a joint. Other organic polymers and inorganic materials can be added to strengthen cartilage scaffolds [2]. Other things like growth factor, adjusting pore structure, injecting bioink via conical needles, and simulating cartilage gradient can all be done to try and improve the hydrogels mechanical properties.

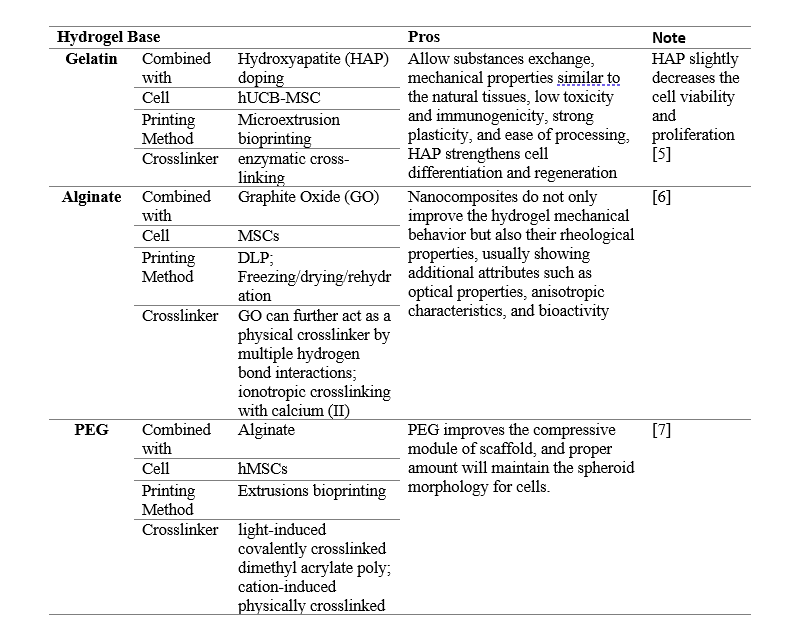

Bio-inks should be shear-thinned and viscoelastic enough to minimize the damage caused to cells by shear forces when using extrusion printing methods. While the physical properties of the bio-ink are important, biocompatibility must be the first priority. This is why a material like polycaprolactone is not considered as a primary bioink in bioprinting even though it has excellent mechanical properties. After printing a quick crosslink could help to maintain the stability of the structure. There are four types of crosslink mechanisms: ionotropic crosslink (eg. CaCl2 for alginate [3]), enzyme crosslink (eg. Enzyme for fibrin [4]), thermal crosslink, photo crosslink. Three typical combinations of 3D-printed hydrogels for cartilage tissue regeneration are reviewed below

Recent Comments